Technology

Physics instead of Voodoo

SCHNERZINGERS INNOVATIVE DEVELOPMENT APPROACH

Our developments are based exclusively on recognized physical principles and laws of electrical engineering.

Our findings flow into innovative product designs that are continuously optimized and validated through inspiration, development work and intensive comparison and listening tests.

The effectiveness and amazing sound improvement can be reproduced again and again - and is unmistakable!

SCHNERZINGER does not use any information or quantum applications and works completely radiation-free.

The Schnerzinger technologies GIGA CANCELING, ATOMIC BONDING and BIDIRECTIONAL BARRIER are the convincing result of years of complex development cycles and the essence of the exceptional capabilities of our products.

Please understand that Schnerzinger aims to protect its innovative technologies from imitation and therefore does not publish detailed modes of operation.

A DECISIVE FOUNDATION &

SYNERGY

SYNERGY

A DECISIVE FOUNDATION &

SYNERGY

SYNERGY

Atomic Bonding

Time-intensive formatting processes lasting several months enable an outstanding and durable conductor material quality that clearly stands out from even the best cryogenically treated monocrystalline OCC conductor materials - in all sound-relevant criteria!

INVISIBLE, YET

SOUND DEFINING

SOUND DEFINING

INVISIBLE, YETSOUND DEFINING

Giga Canceling

Electrical interference sources are processed at high speed up to the three-digit giga range. Effective absorption responses protect the surroundings from sound impairment caused by electrical interference fields.

BEST CHANNELING &SIGNAL PROTECTION

BEST CHANNELING &SIGNAL PROTECTION

Bidirectional Barrier

Interference fields emitted via the power grid, cables and components are consistently blocked or dissipated. In particularly critical environments, the effectiveness can be extensively enhanced with optional Schnerzinger cable accessories.

PERFECT BALANCE

BREATHTAKING SOUND

BREATHTAKING SOUND

CABLE TECHNOLOGY

Unprecedented levels of sound can only be achieved with a perfect coordination of all components. By the synergetic combination of our key technologies ATOMIC BONDING, BIDIRECTIONAL BARRIER and DIELECTRIC CHARGING as well as many more optimizations, we create cables that can raise the potential of your HiFi system to a degree unimagined before.

COMPLEX. UNRIVALED. UNIQUE.

OUR SOLUTION AT A GLANCE

COMPLEX. UNRIVALED. UNIQUE.

OUR SOLUTION AT A GLANCE

ATOMIC BONDING

UNRIVALED CONDUCTOR QUALITY - PERFECT SIGNAL TRANSMISSION

The secret to SCHNERZINGER cable technology lies in what is termed ATOMIC BONDING. These time-intensive formatting processes, which take several months, achieve an outstanding and durable conductor material quality that once again clearly stands out in all sound-relevant criteria - even from the best cryogenically treated monocrystalline OCC conductor materials. ATOMIC BONDINGThese time consuming formatting processes, lasting for several months, impart outstanding conductor material quality that sets itself apart - even from the very best cryogenically treated mono-crystalline OCC conductor material - in all sound-related aspects, in a manner that can best be described as startling.

THE LIMITS OF CONVENTIONAL CONDUCTOR PRODUCTION

To manufacture the conductor material in most audio cables, thick copper or silver strands are repeatedly drawn through so-called drawing dies until the wires are thin enough for further use. Every drawing process means enormous mechanical stress, which causes the crystalline grain structure of the wires to disintegrate into many crystals. In a sense, the audio signals have to find their way through many of these grain structures. The flow through the grain boundaries from grain to grain creates an enormous resistance potential every time, which is known to cause slowed signal transport.

A more complex casting process is therefore often used for higher-quality audio cables. Here, liquid copper or silver is continuously poured into molds (casting molds), creating longer grain structures. In the even more complex monocrystalline OCC or UPOCC (Ultra Pure Ohno Continuous Casting) processes, the molds are even heated and cooled down slowly to prevent the material from solidifying too quickly and to achieve the longest possible crystal structures.

The commonly accepted market practice (special castings, OCC, UPOCC, etc.) symbolically is to combine multiple single ice cubes to longer ice cube chains, to preferably create a monocrystalline structure with less sound damaging gaps. Though under motion, usually even directly after the manufacturing process, long structures quickly break open and fall apart, significantly reducing the theoretical benefit.

ATOMIC BONDING

INNOVATION OF CONDUCTOR TECHNOLOGY

SCHNERZINGER ATOMIC BONDING takes a completely new approach. In a technologically extremely complex process, the focus is not on bonding individual ice cubes into the most closed, long-chain mono-structure possible, as is usually the case, but on crushing the cubes. This produces the smallest ice structure components, which can then be compacted into a stable, homogeneous ice mass with very high cohesive forces in the tube.

A compacted, fused mass of ice has a closed, extremely stable structure - with no gaps in between.

The result is the virtually loss-free transmission of information along with a significant increase in information density, thereby redefining audiophile parameters such as resolution, soundstage, dynamics and musicality.

BENEFITS OF ATOMIC BONDING

- unrivaled approach to conductor treatment

- Durable, extremely stable and compact microstructure of the conductors

- unique conductive properties - limitless resolution & incredibly musical

- maximum authentic signal transport compared to established casting methods

- significant minimization of signal degrading grain boundary transitions

- authentic sound without "tuning"

- time-correct transmission of all frequencies

- handles pulse-currents completely effortlessly

GIGA CANCELING

COMPREHENSIVE, UNIQUE, EFFECTIVE

CONVENTIONAL INTERFERENCE SUPPRESSION TAKES ITS TOLL

Even the highest quality mains filters, power conditioners and battery solutions work with filters, capacitors, resistors, diodes, etc. These components absorb energy and release it with a time delay. This inevitably leads to a decrease in frequency bandwidth and speed. However, these factors are crucial for lively and authentic sound reproduction. The potential of your hi-fi system is therefore far from being fully exploited.

GIGA CANCELING - INTERFERENCE CLEARING OF THE FUTURE

THE FUNCTIONAL PRINCIPLE OF GIGA CANCELING

The SCHNERZINGER GIGA CANCELING TECHNOLOGY has a receiving and a control function:

The receiving function picks up interference frequencies up to the gigahertz range from the environment. The control function processes the received interference frequencies at high speed and absorbs them directly in the device according to the principle of antiphase cancellation.

This is done without the use of filters, capacitors and other compromised components, as well as without quantum or energetic information applications. As a result, the frequency bandwidth and speed of the audio signal are fully preserved.

An important health aspect:

The GIGA CANCELING technology works without radio transmission and does not cause any electrosmog

INDIVIDUAL AND FLEXIBLE

The bandwidth and clock rate of the GIGA CANCELING technology in our PROTECTORS are adjustable. This makes it possible to adapt to any interference field spectrum and to respond to individual hearing preferences. Changing the bandwidth extends or reduces the detection range, while changing the clock rate increases the processing speed.

The rule is: the narrower the bandwidth, the higher the efficiency - the smaller the detection range. The lower the clock rate, the higher the extinction rate - the less interference frequencies are detected.

BIDIRECTIONAL BARRIER

Consistent interference field protection

for unhindered signal transmission

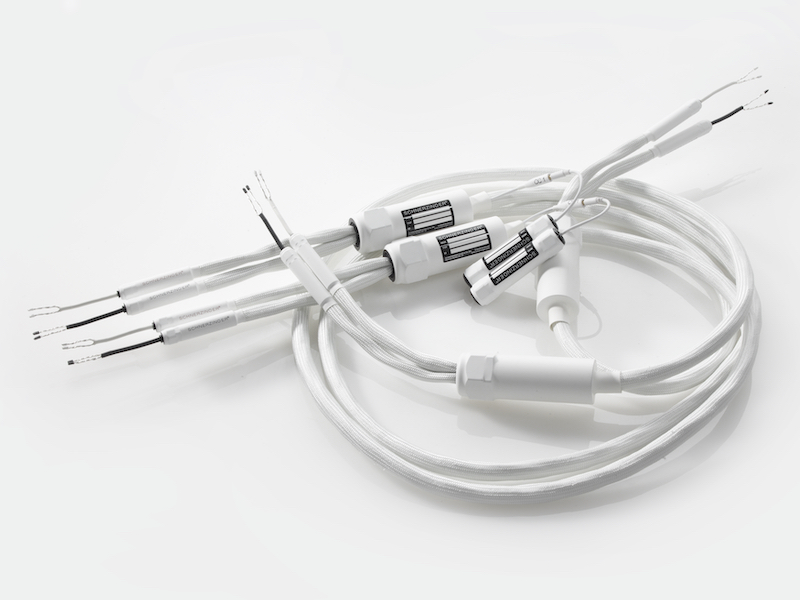

The interference of interference fields via cables is an important and at the same time complex issue, which we pay a lot of attention to when developing our cables. To consistently protect the audio components, all SCHNERZINGER cables therefore have a double interference field protection - the bidirectional barrier.

WORKING PRINCIPLE

The external interference fields emitted via the power supply and cables are blocked and do not enter the signal path. The internal electrical interference fields caused by the hi-fi devices themselves or penetrated into the signal path by external cables are not transmitted to other hi-fi devices, but are diverted to the outside.

In case of very strong interference field loads, the effectiveness of the BIDIRECTIONAL BARRIER can be increased for the cables of the RESOLUTION LINE for the cleaning of external interference fields by an optional power amplifier, the CABLE PROTECTOR

For the RESOLUTION LINE, SCHNERZINGER also offers the optional SIGNAL PROTECTOR, an effective power amplifier for diverting the internal interference fields that have penetrated the signal path to the outside.

Each SCHNERZINGER product operates independently.

The more consistently the interference field protection is built up with our products, the more amazing synergy effects are created.

The consistent use of SCHNERZINGER products creates a closed system in which the important bidirectional mechanism is not interrupted.

THE SECRET OF OUR

CABLE TECHNOLOGY

The intelligently combined application of SCHNERZINGER key technologies opens up an unrivaled and completely new transmission quality of audio signal and power cables.

The full speed signal transmission, cleared of electrical interfering fields, causes a previously unattainable naturalness, detail resolution and spatial representation and thus an unimaginable and incomparable realism of the music reproduction.

Thanks to the outstanding and durable conductor material quality, the unsurpassed dielectric, as well as the highly effective interfering field elimination, SCHNERZINGER CABLE realize loss-free information transmission, the density of which completely redefines audiophile parameters such as resolution, spatial representation, dynamics and musicality.

THE PROBLEM OF INTERFERENCE FIELDS IN CABLES

Due to the sharp increase in radio-controlled transmission technology (WLAN, mobile phones, etc.), the radio frequency load on your HiFi setup has increased significantly. This has an impact, especially on the cables used, as cables attract high-frequency interference fields.

Cable manufacturers therefore go to great lengths to compensate for the negative effects with shielding, filters etc.. Involuntarily, this compromises the potential of your system instead of specifically promoting it.

Our cable technologies therefore do not compensate for the effects of electrical interference fields, but instead specifically address their causes and origins.

HIFI SIGNAL PROTECTION BY SCHNERZINGER

unrivaled, comprehensive, highly effective

ATOMIC

BONDING

CONDUCTOR MATERIAL THAT REDEFINES AUDIOPHILE PARAMETERS

BIDIRECTIONAL BARRIER

Innovative protection from penetrating interfering fields

DIELECTRIC

CHARGING

Perfect dielectric with ultimate transmission properties

BETTER SKIN

ABSOLUTELY COHERENT TRANSPORT OF ALL FREQUENCIES

BETTER FLOW

BEST MATERIAL TRANSITIONS, MINIMIZATION OF RESISTANCES AND RESONANCES

BETTER GEOMETRY

OPTIMALLY COORDINATED LADDER GEOMETRY

VYBRA STOP

EFFECTIVE REDUCTION OF MECHANICAL RESONANCES

RESONANCE CONTROL

EXCELLENT DISSIPATION OF UNAVOIDABLE RESONANCES

ANTIMAGNETIC

REDUCTION OF MAGNETISM TO AN ABSOLUTE MINIMUM

CRYO-FREE

NO DISADVANTAGES LIKE CRYOGENICALLY TREATED SIGNAL CONDUCTORS

ANTISTATIC SHELL

ANTISTATIC CABLE SHEATHING

VOODOO-FREE

SCIENTIFICALLY SOUND INNOVATION

Atomic Bonding

Compared to complex treatment of ultra-pure and long- and mono- crystalline OCC metal structures, this extremely complex formatting processes facilitates an exceptional quality of material: it enables not only a higher information density, but also a transmission performance, which in all relevant sound aspects dramatically departs from previous references and thus questions hitherto cable technologies.

- Unrivaled approach to conductor treatment

- Durable, extremely stable and compact microstructure of the conductors

- Unique conductive properties - limitless resolution & incredibly musical

- Maximum authentic signal transport compared to established casting methods

- Significant minimization of signal-interfering grain boundary transitions

- Authentic sound without "tuning"

- Time-correct transmission of all frequencies

- Processes pulse currents without any effort

UNRIVALED CONDUCTOR QUALITY - PERFECT SIGNAL TRANSMISSION

The secret of SCHNERZINGER cable technology lies in ATOMIC BONDING. This time-intensive formatting process, which takes several months, achieves an outstanding and durable conductor material quality that once again clearly stands out in all sound-relevant criteria - even from the best cryogenically treated monocrystalline OCC conductor materials.

THE LIMITS OF CONVENTIONAL CONDUCTOR PRODUCTION

To manufacture the conductor material in most audio cables, thick copper or silver strands are repeatedly drawn through so-called drawing dies until the wires are thin enough for further use. Every drawing process means enormous mechanical stress, which causes the crystalline grain structure of the wires to disintegrate into many crystals. In a sense, the audio signals have to find their way through many of these grain structures. The flow through the grain boundaries from grain to grain creates an enormous resistance potential every time, which is known to cause slowed signal transport.

A more complex casting process is therefore often used for higher-quality audio cables. Here, liquid copper or silver is continuously poured into molds (casting molds), creating longer grain structures. In the even more complex monocrystalline OCC or UPOCC (Ultra Pure Ohno Continuous Casting) processes, the molds are even heated and cooled down slowly to prevent the material from solidifying too quickly and to achieve the longest possible crystal structures.

The commonly accepted market practice (special castings, OCC, UPOCC, etc.) symbolically is to combine multiple single ice cubes to longer ice cube chains, to preferably create a monocrystalline structure with less sound damaging gaps. Though under motion, usually even directly after the manufacturing process, long structures quickly break open and fall apart, significantly reducing the theoretical benefit.

ATOMIC BONDING– INNOVATION DER LEITERTECHNOLOGIE

SCHNERZINGER ATOMIC BONDING takes a completely new approach. In a technologically extremely complex process, the focus is not on bonding individual ice cubes into the most closed, long-chain mono-structure possible, as is usually the case, but on crushing the cubes. This produces the smallest ice structure components, which can then be compacted into a stable, homogeneous ice mass with very high cohesive forces in the tube.

A compacted, fused mass of ice has a closed, extremely stable structure - with no gaps in between.

The result is the virtually loss-free transmission of information along with a significant increase in information density, thereby redefining audiophile parameters such as resolution, soundstage, dynamics and musicality.

Bidirectional

Barrier

Bidirectional

Barrier

By design each SCHNERZINGER cable builds a bidirectional barrier, without reducing signal bandwidth or signal speed at all: external interfering fields radiating from the power grid or the cables are blocked, internal interfering fields caused by the HiFi devices themselves are not transferred to other HiFi devices.

- BIDIRECTIONAL BARRIERS in all Schnerzinger cables

- Effective protection of the transported signal from irradiating interference fields

- Blocks further transport and superposition of electromagnetic interference

- Preserves the full sound potential and performance of HiFi components

- Prevents the "antenna effect" of shielded audio cables on high frequency

CONSEQUENT INTERFERENCE FIELD PROTECTION FOR UNDISTURBED SIGNAL TRANSMISSION

The interference of interference fields via cables is an important and at the same time complex issue, which we pay a lot of attention to when developing our cables. To consistently protect the audio components, all SCHNERZINGER cables therefore have a double interference field protection - the BIDIRECTIONAL BARRIER.

WORKING PRINCIPLE

The external interference fields emitted via the power supply and cables are blocked and do not enter the signal path. The internal electrical interference fields caused by the HiFi devices themselves or penetrated into the signal path by external cables are not transmitted to other HiFi devices, but are diverted to the outside.

In case of very strong interference field loads, the effectiveness of the BIDIRECTIONAL BARRIER can be increased for the cables of the RESOLUTION LINE for the cleaning of external interference fields by an optional power amplifier, the CABLE PROTECTOR

For the RESOLUTION LINE, SCHNERZINGER also offers the optional SIGNAL PROTECTOR, an effective power amplifier for diverting the internal interference fields that have penetrated the signal path to the outside.

Di-Electric Charging

This technique was designed to avoid electron stream impairment, resulting from dielectric media. The DIELECTRIC CHARGING approach steps out the approach of the best-established insulating material by far. We talk about a time-consuming manufacturing process, to directly counteract the effect of insulating material to slow down and delay electron flow, instead of merely minimizing it by the use of better materials. The result even achieves better transmission properties than pure air.

- Combination of air-filled material & DIELECTRIC CHARGING process.

- Pristine sound & best dielectric properties

- Unrestricted signal flow due to significantly minimized electronic memory effect

- Production without material-damaging high-temperature processes

- Absolutely stable insulation and durable oxidation protection

To prevent electrical short circuits between the wires, they must be insulated. The insulation material, also called dielectric, has an enormous influence on the transmission quality of audio cables. Pure air is theoretically the best dielectric, but it does not insulate. However, in the case of cables marketed in the audio sector with air or AIR insulation, for example, the individual conductor wires are provided with an insulating layer of varnish, which has significantly poorer dielectric values than PTFE, for example. In addition, this insulating layer is often applied using structurally damaging high-temperature processes, which often negatively affect the quality of the conductor's material structure. This is clearly not the case with SCHNERZINGER.

Our test runs utilizing various isolators – starting with best polyethylene PTFE, FEP, across foamed material, natural fabric, like unbleached cotton or silk up to extremely expensive and exotic approaches with costly inert gas and specifically deployed battery voltage - confirm the enormous importance of the often underestimated dielectric.

However, the contradiction between high insulation on the one hand and lowest storage capacity on the other hand could not be solved so satisfactorily with any of these approaches that it did not lead to a limitation of the performance potential of the SCHNERZINGER SIGNAL CONDUCTOR.

Better SKIN

Isochronous transport across all frequency ranges is the SCHNERZINGER conductor construction objective. Traditional solid, bunched, foil or hollow conductor constructions favor the transmission of very specific frequency ranges in each case. Though these designs do not achieve changeless electrical conditions and the associated synchronistic transport of all signal frequencies. BETTER SKIN technology combines the merits of distinct designs, not accepting the downsides.

- BETTER SKIN - optimizes the time-correct transmission of all audio frequencies

- Perfect conductor cross-section - rhythmically enormously captivating, without tonal coloring

- No "tuning", no "Hyper-HiFi" but pure and unadulterated information reproduction

SKIN EFFEKT- Frequency-dependent signal transport in the conductor

An important sound-relevant factor is the so-called skin effect. This can be explained in a very simplified way as follows: High frequencies flow near the surface, medium and low frequencies are oriented more towards the center of the conductor.

For a nearly lossless transport of high frequencies, often flat wire resp. foil conductor, hollow conductor or litz wire (often several distinct isolated strands with very small width) are disposed.

These constructions– having a large surface and a small core portion - favor the transport of high frequencies; but from our experience just this characteristic complicates the desired uniform transmission of low, mid and high frequencies. However or because of that, at first these constructions are often perceived as being more open and having with a higher resolution. In our book for a time correct, natural and not artificially accentuated presentation of the upper spectrum it’s of elementary importance, that all frequencies will be transported holistically. A few of these cable designs also tend to higher capacitance, whereon certain equipment combinations respond with unpredictable performance.

A performance displaced to higher frequencies may be perceived – as mentioned above – as more dynamic and three-dimensional and having higher resolution, but from our experience this is accountable for the so-called hyper hi-fi sound; soon the listener will be stimulated to yet another compensating action and so forth.

BETTER FLOW eliminates unnecessary material changeovers, contact resistance and material resonances. This technique puts aside the usage of compromise afflicted alloying, which enduringly affects the conductivity of a pure signal conductor.

- High-quality connection technology, minimizes sound-destroying material breaks

- No "error compensation" of the cables due to insufficient conductor material quality

- Selected connectors & components, separately treated conductive components

BETTER FLOW LEITERMATERIALGÜTE

Conventional untreated conductor material consists of many short crystalline grain structures, which furthermore conditional of manufacturing are laying in an inappropriate assembly. So to some extend the information has to find its diffuse way through many grain structures. Flowing through the grain boundary junctions from grain to grain implies an enormous resistance potential und thus causes a slowed down signal transmission. In addition information transmission virtually swirls in the grain boundary voids, so tones belonging together are time delayed and torn apart. Above all grain boundary voids allow deformations of the grain structure. This in turn may result in grain contact points, whose resonances may distort the information.

The SCHNERZINGER ATOMIC BONDING conductor material minimizes these sound-influencing effects by providing a permanently compact and enormously homogeneous microstructure of the conductor.

CONNECTOR - COMPONENTS, MATERIAL

Our research shows, that the parts performance potential is primarily determined by the crystalline structure of the deployed material rather than by the material itself. Performance deficits because of a non-optimum crystalline material structure of a connector plug may be compensated via clever actions.

With many connector plugs in the audio domain a layer of gold, silver, rhodium, palladium etc. will be added to the conducting material. This improves electrical contact and - via the distinct character of the particular plating - it furthermore allows for compensation of deficits.

But we strive for the solution, not just a compensation of a problem, so we employ connector plugs that are adjusted to the fabric of the SCHNERZINGER CONDUCTOR via the complex process ATOMIC BONDING. We disassemble all plugs into their individual parts and replace the contact pins by ATOMIC BONDING formatted pins. To perfectly protect the contact pins against interfering fields and to establish double operational reliability, the plug receives a two-shelled housing. To reduce contact resistance, after assembly plugs and conductor together will be ATOMIC BONDING processed once again.

Compared to the complexity and effect of these actions the significance of the original material characteristic is secondary.

The decision in favor of the now employed connector plugs was done after a multitude of comparisons utilizing the best respected plugs and sockets of the world market.

Price and reputation of the tested devices were of minor importance, as the costs of ATOMIC BONDING by far exceed the costs of expensive plugs.

We explicitly indicate, that - because of the structural adjustment of plugs and conductor material - any back fitting to other plugs will drastically degrade sound quality, thus irreparably destroy the SCHNERZINGER original connection.

Common conductor geometrics, e. g. binding, parallel and twist designs are afflicted with gains, but also with significant losses. BETTER GEOMETRY allows benefiting from the gains, thus minimizing the losses.

- Uses the advantages of established designs without accepting their disadvantages

- Perfect conductor cross-section - rhythmically enormously captivating, without tonal coloring

- No braided fabrics made from statically problematic plastics

- Avoidance of material-damaging heat processes

GEOMETRY - twisting, interlacing or parallel cable constructions

The design of a cable must be mechanically stable, create a homogeneous electromagnetic field between and around the conductors, and ensure the time-correct, and loss-free signal flow.

Efforts to use elaborate stranding and braiding techniques to counteract the problems of mutual interference often fail.

Twisted constructions reduce the susceptibility to interference, and typically result in a low inductance, which is usually targeted. However, as soon as current flows through a wire, its own electromagnetic field is generated. If the cores are twisted, the electromagnetic fields of the individual wires are close together over a large area, acting on each other and impairing the flow of electrons, which is why solid conductors are often used instead of stranded wires.

Braided constructions also typically reduce susceptibility to interference, but accept the effects of a constant but permanent change in the electrical environment of the individual conductors relative to each other, and it is this that leads to electromagnetic clutter, which in turn affects electron flow.

Parallel constructions with conductors running in parallel are not very resistant to external interference fields and favor the proximity effect, which also impairs the flow of electrons due to eddy currents that are generated.

To realize a full speed and even electron flow, the electrical parameters and the electromagnetic fields should remain constant and homogeneous across the entire cable length. The requirement of a mechanically stable design is often underrated, although this is an important factor in order to adhere to constant conditions.

In order to take full advantage of close-meshed interlocking constructions without accepting their electromagnetic problems, SCHNERZINGER relies on a combination of intelligent superstructures and revolutionary technology:

BETTER GEOMETRY uses a high-tech process to directly absorb electrosmog and virtually neglect resulting electromagnetic problems.

CABLE COATING – static problem catcher

Plastic fabric hoses are used by many manufacturers as outer sheathing. They look fancy, are inexpensive, and make manufacturing easier. But the fact is that the outer jacket definitely affects the sound quality of a cable.

In the case of plastics, for example, static charges can occur that impair electron transport.

As a so-called "tuning measure", antistatic agents are then often offered as accessories to counteract the inadequacies of these materials.

We therefore deliberately dispense almost entirely with plastic fabric tubes, which may make a cable appear professionally manufactured, but in our opinion do not belong in a sonically consistent development chain.

Mechanical vibrations of signal conductors generate resonances, varying the electrical relationship between the conductors and smudging information. VYBRA STOP lessens mechanical vibrations of the current carrying conductors.

SCHNERZINGER does not apply cryogenical treatments. As a final stage special processes are used, to produce a more efficient and especially permanent and persistent effect.

- No use of only temporarily improving and permanently damaging treatments of the conductor material

- Durable and unrivaled material integrity of the conductors thanks to ATOMIC BONDING technology

Cryogenic processes used in the metal industry for decades have been marketed in the audio domain for some time now. The material to be treated is cooled down in professional, computer - controlled cryo - facilities in definite intervals to about -150 to -196°C and lower, staying at the trough, to subsequently raise the temperature again. In doing so nitrogen or even deeper cooling substances are used.

In our opinion the performance of these quite cheap cryo treatments shows an adequate price / value ratio, but as our test runs show, these treatments exploit only a fraction of the really attainable potential; they also seem to diminish over time.

We definitely advise against the common method of simply dipping the materials into a nitrogen filled container. Our experience shows that the material structure may break over time by such an „extreme chilling“; thus after an initial improvement the sound characteristic may harden more and more.

Thanks to the revolutionary approach of ATOMIC BONDING, SCHNERZINGER CABLES, on the other hand, are permanently convincing and without any potentially negative effects of the treatment on the microstructure quality of the conductor material.

While the VYBRA STOP technology is designed to prevent the development of disturbing resonances, the aim of RESONANCE CONTROL is to eliminate existing resonances by transforming them into areas that are not harmful to the sound.

Several special demagnetizing processes decrease the residual magnetism to a minimum.

OUR PORTFOLIO

LEARN MORE

PROTECTORS

CABLE