UNLIMITED RESOLUTIONINCREDIBLY MUSICAL

Listen without compromise. Experience music perfectly.

Our innovative high-tech interference suppression and audio signal protection creates an audiophile experience at a unique level.

FINALLY...LANTASTIC SOUND

FINALLY...LANTASTIC SOUND

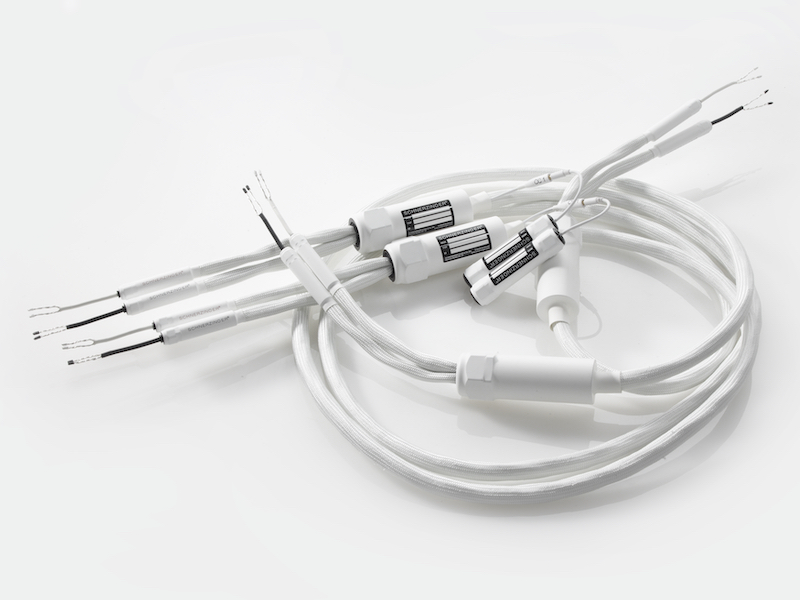

LAN PROTECTOR

STREAMING MEETS HIGH TECH

What previously seemed impossible is now a reality: our LAN PROTECTOR is a real revolution in music streaming. Enjoy interference-free data transmission in your network at a level that you would never have thought possible before.

WHAT MAKES SCHNERZINGER SO UNIQUE?

Our innovations are high-tech at its best and leading in the audio and HiFi scene.

With our products you can achieve a sound level that fully exploits the potential of your hi-fi system.

The result: a completely realistic and at the same time puristic sound experience that will completely inspire you.

NATURAL

PRESENCE

comprehensive signal cleansing

EMOTIONAL

DELIGHT

incredibly pure music experience

CRYSTAL CLEAR

TRANQUILITY

unhindered signal transmission

DIE STÖRQUELLEN

Was beeinträchtigt Ihre Hifi Anlage?

Was beeinträchtigt Ihre Hifi Anlage?

DIE HERAUSFORDERUNGEN

Was stört Ihre Hifi Anlage?

Was stört Ihre Hifi Anlage?

COMPLEX. UNRIVALED. UNIQUE.

THE SCHNERZINGER SYSTEM

COMPLEX. UNRIVALED. UNIQUE.

THE SCHNERZINGER SYSTEM

PURE PASSIONFOR THE TRUE SOUND

PURE PASSION

FOR THE TRUE SOUND

PROTECTORS

Innovative interference suppression at highest level

WLAN, DECT, mobile phones, electrical devices, power lines, etc. can have a strong influence on the sensitive audio signal.

Thanks to our pioneering GIGA CANCELING technology, our protectors and guards effectively prevent electrical interference fields and contribute to an unrivalled sound experience.

CABLE

Unbelievably pure signal transmission

The secret of our cable technology lies in ATOMIC BONDING: time-consuming formatting processes lasting several months achieve an outstanding and durable conductor material quality.

Combined with our BIDIRECTIONAL BARRIER, we achieve unrivalled purity in signal transmission.

POWER

Pure and unrestrained power distribution

Thanks to the ATOMIC BONDING formatted conductor material, even the highest current pulse peaks are completely unchecked.

In addition, every SCHNERZINGER POWER PRODUCT provides efficient protection against internal and external interference field transmissions thanks to its BIDIRECTIONAL BARRIER.

FOR THE LOVE OF MUSICOUR MANUFACTURY

Product development was a long and passionate search for the perfect sound and how it is created.

The focus of development has always been on the timely and undisturbed transmission of signals. And the search for the absolutely perfect components, their targeted technical optimization and the ideal combination of all components.

Every development step was a great incentive for us. Because it became clear time and again how important the perfect quality of the conductor material and an interference-free environment are for an incomparable listening experience.

EXTENSIVE PROTECTIONEXTRAORDINARY RESULTS

EXTRAORDINARY RESULTS

(R)EVOLUTIONARY. INNOVATIVE. UNIQUE. HIFI EVOLUTION AT THE HIGHEST

LEVEL

(R)EVOLUTIONARY. INNOVATIVE. UNIQUE.

HIFI EVOLUTION AT THE HIGHEST

LEVEL

HIFI EVOLUTION AT THE HIGHEST LEVEL

A DECISIVE FOUNDATION &

SYNERGY

SYNERGY

A DECISIVE FOUNDATION &

SYNERGY

SYNERGY

Atomic Bonding

The secret to SCHNERZINGER cable technology lies in what is termed ATOMIC BONDING. These time consuming formatting processes, lasting for several months, impart outstanding conductor material quality that sets itself apart - even from the very best cryogenically treated mono-crystalline OCC conductor material - in all sound-related aspects, in a manner that can best be described as startling.

INVISIBLE, YET

SOUND DEFINING

SOUND DEFINING

INVISIBLE, YETSOUND DEFINING

Giga Canceling

SCHNERZINGER GIGA CANCELING application is a trendsetting technology, processing electrical current in high speed right up to triple-digit gigahertz territory. Thereby a dejamming signal will be generated to effectively protect the environment from losing sound quality by means of scientifically physics.

BEST CHANNELING &SIGNAL PROTECTION

BEST CHANNELING &SIGNAL PROTECTION

Bidirectional Barrier

SCHNERZINGER CABLE and POWER products are designed to work with a BIDIRECTIONAL BARRIER, which blocks or diverts radiated interference fields via the power supply, cables and components. The effectiveness of the BIDIRECTIONAL BARRIER can be further enhanced in critical environments by optional accessories.

Press reviews