Die folgenden Ausführungen geben unsere in jahrelangen wissenschaftlichen Entwicklungsreihen gesammelten Ergebnisse für ein störungsfreies Elektronenflussverhalten innerhalb elektrisch leitender Materialien wieder.

Sie spiegeln ausschließlich unsere eigenen Erfahrungen zu den einzelnen Sachverhalten ohne Anspruch auf Vollständigkeit, Allgemeingültigkeit und Richtigkeit.

Für ein besseres Allgemeinverständnis sind die Erkenntnisse unserer Forschung im Folgenden stark vereinfacht dargestellt.

Kabel

Der Klangkiller Nr. 1 - Fehlerkompensation

Im Audiobereich wird oft versucht, durch fehlerbehaftete Komponenten andere Fehler zu kompensieren.

Aus Erfahrung wissen wir, dass fehlerkompensierende Lösungen grundsätzlich nur zu einer kurzfristigen Zufriedenheit führen und ein Verlangen nach ständigem Wechsel von High-End-Produkten mit dem Ziel einer vermeintlichen „Optimierung“ nach sich ziehen.

Die Folge sind Musikanlagen, auf denen nur ein Bruchteil der gesamten Musiksammlung gut klingt – was meistens mit einer schlechten Aufnahmequalität entschuldigt wird. Hi-Fi-Begeisterte schalten dann üblicherweise nur noch zwischen den auf ihrer speziellen Anlage besonders gut klingenden Musiktiteln hin und her.

Hochwertige Audiosignalverbindungen z.B. werden meist durch die geschickte Zusammenführung und Optimierung der Bestandteile (Leitermaterial, Dielektrikum, Geometrie etc.) eines Kabels entwickelt. Dabei wird häufig versucht, die Unzulänglichkeiten der einzelnen Komponenten gegenseitig zu kompensieren.

In den SCHNERZINGER Entwicklungsreihen ließ sich zum Beispiel ein aggressiver oder wenig ausdruckstarker Klangcharakter unzureichender Materialien, oder Grundkonstruktionen mit geschickten Maßnahmen (Vermischungen von verschiedenen Leitermaterialien/Legierungen, speziellen Geometrien, Ferritkernen, Lacküberzügen etc.), harmonischer ausbalancieren. So bot sich sogar die Möglichkeit, einen eigenen Sound zu gestalten, welcher ähnliche Auswirkungen wie der Dreh am Höhen-, Mitten- oder Bassregler eines Verstärkers hat.

Geschickt eingesetzt mag das über einen gewissen Zeitraum ansprechend sein. Leider behindert unseren Erkenntnissen nach gerade dies einen nachhaltigen klanglichen Fortschritt – den ungebremsten und zeitrichtigen Signaltransport aller Frequenzen

Zum einfachen Verständnis betrachte man exemplarisch die Wiedergabe des angeschlagenen Fells einer Trommel. Die durch den Lautsprecher wiedergegebene Information sollte idealerweise die gleiche Energiemenge mit gleichem Zeitablauf aufweisen wie das ursprünglich angeschlagene Fell. Das sogenannte ‚Ausbalancieren‘ führte in unseren Versuchsreihen immer zu einem gehemmten Elektronenfluss. Anschaulich gesehen bremsen die Lautsprechermembranen dadurch sozusagen mit Verzögerung und schwingen nach, der Ursprungsinformation wird so zusätzliche Energie zugeführt.

Diese zusätzliche Energie kann unterbelichtete oder aggressive Bereiche auffüllen oder überdecken, einen Bass druckvoller, den Mittenbereich präsenter/schönender oder den Hochtonbereich heller und vordergründig auflösender erscheinen lassen.

Derart gezielt verursachte Phasenverschiebungen können durch Auslöschungen auch Energie entziehen. Einer ansonsten aufgedickten Tieftonwiedergabe kann so Energie entzogen werden und drahtiger wirken. Auch die räumliche Abbildung kann für einen nicht ausreichend geschulten Hörer so vordergründig „besser“ erscheinen.

Stellen sie sich dazu bitte den Halbkreis eines Orchesters vor: Schrumpft z:B. die Tiefe, wird die Rauminformation kompakter, flächiger. Dadurch erscheinen die mittleren Reihen weiter vorne und wirken so für einen ungeübten Hörer präsenter. Eine Stimme kann so weiter nach vorne rücken, plastischer und körperhafter wirken. Oft wird gerade durch ungeeignete Musikstücke oder Beurteilungsgewohnheiten

(z. B. wenig komplexe Musikstücke, auf einer Ebene aufgenommene Instrumente/Gesangsstimmen mit künstlicher Räumlichkeit oder die alleinige Konzentration auf eine Stimme oder ein Instrument) ein besseres Produkt im Vergleich schlechter bewertet.

Für eine unverfälschte, authentische, den Hörer langfristig fesselnde Wiedergabequalität müssen die einzelnen Informationen des Ursprungsstücks bei der Übertragung genauso gebündelt wiedergegeben werden, wie sie bei der Aufnahme des Stückes eingefangen wurden – nicht gestückelt, nicht auseinandergezogen, sondern in der richtigen Lautstärke, in der richtigen Reihenfolge und vor allem in der korrekten, zeitlichen Signalfolge.

Der Schlüssel hierzu ist der ungebremste, zeitgleiche und störfeldbereinigte Signaltransport aller Frequenzen – manipulierende Maßnahmen reißen den Informationsfluss auseinander.

Das SCHNERZINGER ATOMIC BONDING und die SCHNERZINGER CABLE PROTECTION wurden mit dem Anspruch einer vollständigen Bereinigung der einzelnen Problembereiche der elektrischen Kabelverbindung entwickelt, um so die begrenzenden Auswirkungen von Kompensationsmaßnahmen zu vermeiden.

RAUMABILDUNG - Warum erzeugen SCHNERZINGER Verbindungen eine solch greifbar plastische Räumlichkeit?

Nachhall, Schallabsorption, Schallschatten, Signallaufzeiten und die Richtungsempfindlichkeit des Außenohrs erlauben uns räumliches Hören. Unser Hirn nutzt dabei den Laufzeitunterschied des Schalls von einem zum anderen Ohr.

Wie schnell und präzise bzw. ungebremst deshalb ein Wiedergabesystem arbeiten muss, um räumliche Informationen exakt zu übertragen, verdeutlicht folgendes Rechenbeispiel:

Der Schall breitet sich in der Luft mit 340 m/s aus, der Kopfdurchmesser beträgt ca.17 cm. Dann beträgt die Laufzeitdifferenz vom linken zum rechten Ohr von einer Schallquelle die 3 Grad von der Mitte des Gesichtes nach rechts abweicht nur ca. 30µs.

Man beachte dabei: Ein Nervenimpuls ist etwa 100mal länger.

Stellt man sich nun den Halbkreis eines Symphonieorchesters vor und füllt diesen mit Instrumenten, kann man sich vorstellen, welche Anforderungen an ein Wiedergabesystem gestellt werden, um die Ortung einzelner Instrumente zu ermöglichen.

Ein präziser, gleichzeitiger und ungebremster Informationstransport ist deshalb für die echte räumliche Wiedergabe von Instrumenten und Künstlern unabdingbar.

Da selbst vielen Fachleuten nicht bewusst ist, dass gerade Kabelverbindungen den Informationstransport arg verschleifen, wird die Wichtigkeit der Audioverbindungen unterschätzt. Leider liegen die Fehler marktüblicher Kabel immer noch in Bereichen, die die tatsächliche Bedeutung der Kabelgüte für das gesamte Klangerlebnis nicht erkennen lassen. So werden viele Hörer verunsichert.

Das SCHNERZINGER ATOMIC BONDING öffnet das Fenster zu einem unverfälschten, ungebremsten und zeitrichtigen Transport von elektrischen Informationen, dessen klangliche Auswirkungen weit über gewohnte Maßstäbe hinausgehen.

Warum entwickeln Sie mit solch teurem Equipment, höre ich das denn bei mir auch?

Der umfangreiche Gerätepark höchstwertiger Komponenten ermöglicht uns das Vordringen in Grenzbereiche, in denen innovative Lösungen entstehen, und nicht einfach fehlerkompensierende Lösungen mängelbehafteter Komponenten, denn langjährige Erfahrungswerte zeigen, dass ein Trugschluss in der Annahme liegt, fehlerkompensierende Lösungen würden zu einer langfristigen Zufriedenheit führen. Dem ist nicht so.

Fehlerkompensierenden Maßnahmen rauben der Musik Ihre einzigartige Authentizität und führen nur zu einer kurzfristigen Zufriedenheit, die weitere, ständige Experimente mit vermeintlich „besseren“ Produkten nach sich ziehen.

Umfangreiche Investitionen in hochwertigstes Referenzequipment sind für eine wahrhaftige Kontrolle der Entwicklungsergebnisse de facto absolut unabdingbar.

Die klanglichen Auswirkungen der SCHNERZINGER Produkte sind selbst in sehr preiswerten und mit Bedacht ausgewählten Anlagenzusammenstellungen außergewöhnlich.

Warum bietet SCHNERZINGER Kabel mit Laufrichtung an?

LAUFRICHTUNG

Bedingt durch die zielgerichteten mechanischen Herstellungs- und komplexen Formatierungsprozesse des ATOMIC BONDING besitzen alle SCHNERZINGER Kabel eine eindeutig definierte „Laufrichtung“, d.h. eine für den elektrischen Signaltransport optimierte Sender-zu-Empfänger-Orientierung für klanglich herausragende Ergebnisse.

Diese optimierte Beschaffenheit manifestiert sich sowohl auf mikromolekularer (kristalline Struktur und Genese des Leitermaterials), als auf makrostruktureller Ebene des Kabels (Aufbau, Schichtung, Geometrie).

Für den Anwender ist die bei Fertigung in unserer Manufaktur zu berücksichtigende Laufrichtung der SCHNERZINGER Kabel äußerlich eindeutig erkennbar – durch die in Richtung des optimalen Signalflusses lesbaren SCHNERZINGER Logos – und für einen optimalen Einsatz des Kabels unbedingt einzuhalten.

Warum bietet SCHNERZINGER Stromkabel mit PHASE L und PHASE R an?

SCHNERZINGER Stromkabeln weisen – neben der Laufrichtung – noch ein weiteres Orientierungskriterium auf: Die Auswahl der Lage des Phasenleiters im Kabel. Der Stromfluss zum Verbraucher soll in Laufrichtung und mit Formatierung des Kabels und nicht entgegen dieser Optimierung erfolgen.

Als Phase (Phasenleiter oder L für „line conductor“) bezeichnet man den stromführenden Zuleiter, der den Netzstrom zur Steckdose und von dort zum Verbraucher führt. Der Neutralleiter (Null-Leiter oder N für „neutral) führt den Strom vom Verbraucher zurück ins Netz. Ein Schutzleiter (Erdung, Abkürzung „PE“ von protective earth) leitet potenzielle Körperströme zur Erde ab.

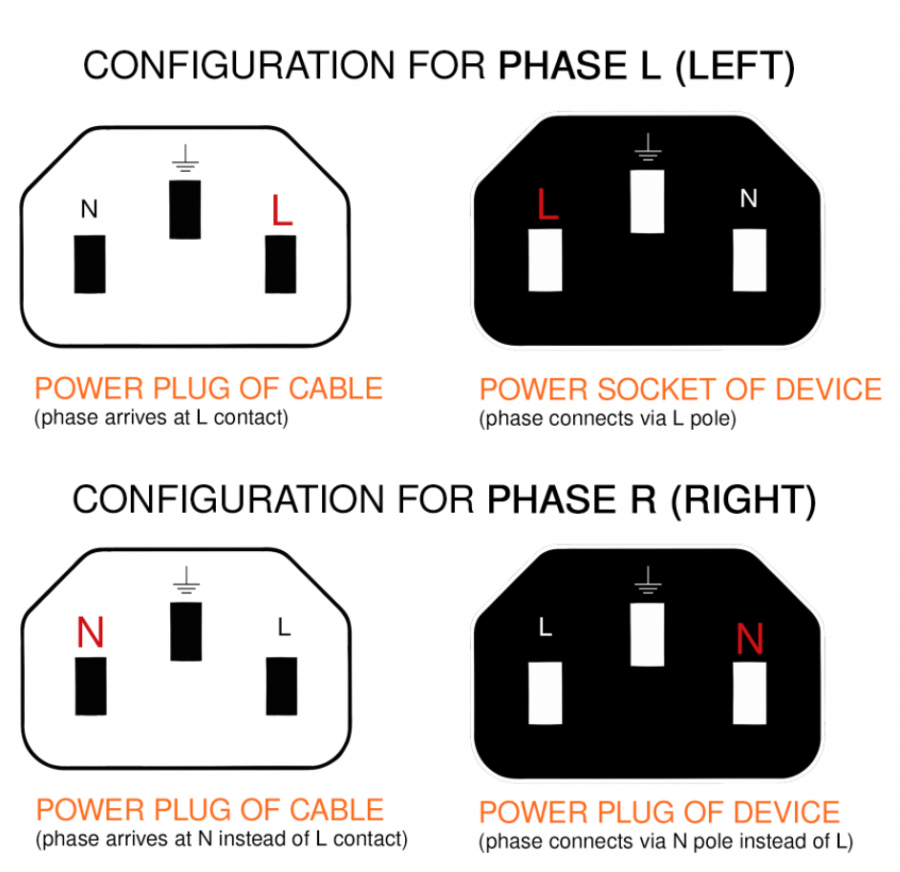

SCHNERZINGER Stromkabel können wahlweise mit definierter Phase L (Links) oder Phase R (Rechts) bestellt und gebaut werden um perfekte Ergebnisse am angeschlossenen HiFi-Gerät zu erzielen:

DEFINIERTER PHASENLEITER im SCHNERZINGER Kabel

Da viele HiFi-Hersteller für den audiophilen Betrieb ihrer Geräte an der jeweiligen Netzanschlussbuchse den optimalen Pol für den phasetragenden Leiter definieren, kann von hier ausgehend für das SCHNERZINGER Stromkabel ebenfalls festgelegt werden, an welchem Pol der Gerätebuchse der phasentragende Leiter des Kabels vom Netz aus „ankommen“ soll (Phase L = „ankommend“ am Polstift für Phase L oder alternativ als Phase R = „ankommend“ am Pol für Null-Leiter N).

Der durchgehende Phasenleiter im Kabel wird von SCHNERZINGER durch eine Markierung (silberner Punkt) am entsprechenden Steckerpol beider Kabelenden gekennzeichnet.

Die Bestimmung der anliegenden Phase in der Steckdose selbst erfolgt z.B. durch einen handelsüblichen Spannungsprüfer (Ausphasen). Auch hier empfiehlt sich im Nachgang die Markierung des Phasenleiters an der Steckdose. Dieser Schritt entfällt an verpolungssicheren Steckdosen, wie z.B. in den USA (US-NEMA), da dort nur eine passende Einsteckrichtung in Frage kommt und die Lage des phasentragenden Leiters an der Steckdose eindeutig definiert ist.

Fazit:

Phasenrichtiger Anschluss der Stromverbindung und richtige Auswahl bzw. Zuordnung der Lage des phasentragenden Leiters im Stromkabel (entweder Phase L oder Phase R) im Verhältnis zum Geräteanschluss gewährleisten die maximale Performance der SCHNERZINGER Powerkabel.

Was bedeutet der Zusatz "HC" bei manchen Schnerzinger Stromkabeln?

Was bedeutet „HC“ bei Schnerzinger Power Cords?

Bei den Stromkabeln der RESOLUTION LINE bietet Schnerzinger einen alternativen Aufbau der Stromkabels – mit aufwendigerer Konstruktion und kostenintensiverem Herstellungsprozess – als sogenannte „High Current“ HC-Variante an.

Abhängig von den Qualitätsstufen der Linie, existieren folgende Optionen:

RESOLUTION ONE: normale Variante

RESOLUTION TWO: wahlweise normale oder HC-Variante

RESOLUTON THREE & FIVE: HC-Variante ist Konstruktionsstandard

Die „High Current“ HC-Variante zeichnet sich im direkten Vergleich zur normalen Version des Stromkabels in allen Parametern durch eine noch überzeugendere Performance aus und wurde insbesondere für den Einsatz an leistungsbedürftigen oder mit Schaltnetzteilen ausgestatteten Komponenten des HiFi-Systems entwickelt, u.a. um besser auf die extremen Stromimpulsspitzen solch hochgetakteter Netzteil-Ladungen und dabei verstärkt auftretenden HF-Störnebeln reagieren zu können.

Tatsächlich profitieren in der Praxis jedoch auch genügsame oder mit linearen Netzteilen konstruierte Systemkomponenten spürbar vom optimierten Aufbau des High-Current Stromkabels, so dass deren Verwendung uneingeschränkt empfohlen werden kann.

Protectoren

Warum ist die STROMVERSORGUNG so klangentscheidend?

Störfelder im Bereich der Stromversorgung

Insbesondere im Bereich der Stromversorgung kommt es zu gravierenden klanglichen Beeinträchtigungen, weil sich:

- A. die durch das städtische Stromnetz und das Hausnetz (Computer, Kühlschrank etc.) eindringenden Störfelder,

- B. die durch die einzelnen Audiogeräte selbst verursachten Störfelder (Trafos, Schaltnetzteile etc.),

- C. die durch die Erdung (Ground) der Audiogeräte entstehenden Potentialausgleichströme und

- D. die durch die Antennenfunktion der Netzkabel aus der Umgebung in die Audiogeräte einstrahlenden hochfrequenten Störfelder (WLAN, Handys etc.)

in der Netzleiste / im Verteiler vermischen und dann in komplexer Form über die Netz- und Signalverbindungen zurück in die Geräte fließen und verteilen und dadurch im höchstem Maße die Übertragungsqualität der Audiogeräte einschränken.

In der Vermischung und Verteilung der elektrischen Störfelder auf alle Geräte liegt der technische Hintergrund, weswegen der „letzte Meter“ Netzkabel inklusive der Netzleiste so klangentscheidend ist. Ein durchgängiges, aufeinander abgestimmtes Gesamtsystem ist daher essenziell.

SCHNERZINGER® Gesamtsystem zur Störungsminimierung

SCHNERZINGER® stellt mit dem INNOVATOR bzw. OPERATOR, den POWER CORDS und der CABLE PROTECTION ein in sich verzahntes Hightech-Gesamtsystem bereit, so dass Störungen bei einem durchgehend SCHNERZINGER® verkabelten Stromsystem nicht mehr zwischen den einzelnen Geräten übertragen werden können; eine sehr wichtige Voraussetzung, ohne die die Überlegenheit der SCHNERZINGER® Stromprodukte gravierend geschmälert wird.

Unterstützung durch die GIGA CANCELING Technologie

Unterstützt wird dieses System durch die GIGA CANCELING Technologie für die Anwendungsbereiche POWER (Strom), COMPONENT (HiFi-Geräte) und ROOM (HiFi-Raum), welche die Audioanlage:

- vor den von außen eindringenden,

- vor den inneren selbst verursachten,

- und vor den durch die Raumumgebung einwirkenden äußeren Störfeldern schützt.

Auswirkungen von Störungen auf die Klangqualität

Die Beeinträchtigungen durch elektrische und elektromagnetische Störungen sind massiv und können sich unter anderem folgendermaßen auswirken:

- ein Verlust an Auflösung

- ein Verlust an Dynamik

- ein künstlicher, mitunter scharfer Hochtonglanz

- eine geminderte räumliche Abbildungsfähigkeit

- eine in den Mittenbereich verschobene Frequenzbalance

- zeitliche Verschiebungen bzw. Phasenprobleme

Können andere Produkte die Funktionsfähigkeit von SCHNERZINGER PROTECTOREN negativ beeinflussen?

Die GIGA CANCELING Technologie arbeitet mit einer extremen Bandbreite und Geschwindigkeit. Produkte, die sich generell begrenzend oder bedämpfend auf Bandbreite und Geschwindigkeit auswirken, können die Effektivität der GIGA CANCELING Technologie einschränken.

Funktioniert WLAN noch, wenn SCHNERZINGER PROTECTOREN verwendet werden?

Eine der Herausforderungen bei der Entwicklung der GIGA CANCELING Technologie war die uneingeschränkte Funktionsfähigkeit von funkgesteuerten Geräten. Uns ist kein Fall bekannt, in dem die Funktionsfähigkeit eines funkbetriebenen Gerätes nicht mehr gewährleistet ist.

Was unterscheidet die SCHNERZINGER GIGA CANCELING Störfeldbereinigung von atmosphärischen, energetisch informierten Elektrosmog-Produkten?

GIGA CANCELING vs. Informierte (Quantum-) Anwendungen

Im Gegensatz zu den im Audiobereich immer häufiger eingesetzten informierten (Quantum-) Anwendungen, welche ebenfalls ohne limitierende, konventionelle Bauteile – wie z.B. Kondensatoren, Dioden oder Widerstände – wirken, ermöglicht die GIGA CANCELING Technologie von Schnerzinger eine elektrotechnisch fundierte, kontrollierbare und gleichzeitig dauerhafte Bereinigung klangschädlicher Störfelder.

Die oft kritisch diskutierte Verwendung informierter (Quantum-) Produkte gründet in Grenzbereichen feinsinnlicher und atmosphärischer Aspekte. Die Effekte einer gelungenen Informierung sind für das filigrane Gehör evident wahrnehmbar und daher zweifelsfrei wirksam.

Im Audiobereich wirken informierte (Quantum-) Anwendungen jedoch mit gravierenden Nachteilen und über die Zeitachse überwiegend negativ auf das klangliche Ergebnis und unterscheiden sich daher grundlegend von der GIGA CANCELING Technologie von Schnerzinger:

Nachteile: Informierung / Quantum-Anwendung

- Nur temporär positive Effekte auf das Klangbild

- Schleichende Verschlechterung der initialen Verbesserung

- Bedämpfen und überlagern Störfelder, bereinigen aber nicht

- Kein kontrollierbarer Anziehungs- und Filtereffekt

- Anfällig gegen Magnetfelder (veränderte Klangwirkung)

- Wachsende Vermischung informierter Muster (Anziehung/Abgabe)

- Stetige & sorgfältige Reinigungsintervalle notwendig

Vorteile: GIGA CANCELING von Schnerzinger

- Dauerhaft positive Effekte auf das Klangbild

- Kein gradueller Wirkungsverlust über die Zeit

- Effiziente Störfeldbereinigung ohne Bedämpfung

- Kein Verlust von Bandbreite und Geschwindigkeit

- Authentische Offenbarung des klanglichen Potentials

- Keine täuschenden Fehlerkompensationen

- Einfaches Handling nach initialem Setup

Hintergrundinformation: Informierte (Quantum-) Anwendungen

Energetisch informierte, atmosphärische Quantum-Elektrosmog-Produkte funktionieren, indem sogenannte energetische Schwingfelder auf geeignete, speicherfähige Trägermaterialien wie z.B. Kohlenstoff, Edel- und Halbedelsteine, Glaskörper oder mit geeigneter Trägerschicht versehene Chips (Energy Cells) aufgebracht und gespeichert werden. Diese Trägermaterialien geben dann im Zeitverlauf die gespeicherten energetischen Schwingfelder an die Umgebung ab.

Da die informierte Anwendung elektrische Störfelder nur mit Schwingfeldern überlagert und bedämpft und nicht wirklich bereinigt, sind ihre Auswirkungen limitiert und insbesondere langfristig nicht nur positiv zu bewerten:

Durch die Informierung werden Trägermaterialien aktiviert. Sie geben danach zuvor gespeicherte Informationen ab, ziehen jedoch gleichzeitig und deutlich verstärkt auch Informationen aus der Umgebung an und speichern diese.

Nach Aktivierung entsteht in der Folge so ein Gemisch aus aufgebrachten Informationen und angezogenen Informationen, welche wieder zusammen an die Umgebung abgegeben werden. Je stärker die Informierung, je größer die Speicherfähigkeit der Trägermaterialien, desto stärker ist dieser Anziehungseffekt.

Das hat auf Dauer nicht zu unterschätzende Konsequenzen: Weil der Anziehungseffekt nicht kontrollierbar oder filterbar ist, werden auch schädliche Informationen mit der Zeit (und zwar deutlich verstärkt durch die Aktivierung) angezogen, gespeichert und wieder an die Umgebung abgegeben.

Damit negative Informationen sich nicht schädlich auf die Umgebung und den Klang auswirken, müssen die informierten Materialien regelmäßig (am besten täglich) gereinigt werden. So kann sichergestellt werden, dass nur die gewünschten positiven Ursprungsinformationen auf den Trägermaterialien verbleiben. Im Audiobereich z.B. sind die klanglichen Auswirkungen nach einem gelungenen Reinigungsprozess der Quantum Produkte wieder deutlich effektiver.

Die Reinigung geschieht unter fließendem, nicht stehendem Wasser, Sonnenlicht oder wechselnden Magnetfeldern. Dabei gilt folgende Faustregel: je größer und reiner die Wassermenge, je intensiver das Sonnenlicht oder je stärker das wechselnde Magnetfeld, desto intensiver ist der Reinigungseffekt. Je länger die Informationen auf dem Trägermaterial gespeichert sind, desto schwieriger gelingt ein vollständiger Reinigungsprozess. Jeder Reinigungsprozess sollte bei informierten Materialien individuell angepasst werden, weil ein zu intensiver Reinigungsprozess auch die informierte Ursprungsinformation löscht, ein zu niedriger dagegen die schädlichen Informationen nicht hinreichend beseitigt.

Deshalb sollten Quantum Produkte nicht starken Entmagnetisierern oder Magnetfeldern ausgesetzt werden, da sich dadurch ihre Wirksamkeit und ihre klanglichen Auswirkungen verändern.

Was bewirken Edel- und Halbedelsteine, Bergkristalle, Rosenquarz, Turmalin, etc.?

Von Edel- und Halbedelsteinen, Bergkristallen, Rosenquarz, Turmalin etc. gehen aufgrund ihrer hohen Speicherfähigkeit sehr starke in Hunderten von Jahren in der Natur entstandene natürliche energetische Informationen aus. Zudem besitzen diese Gesteine einen Reinigungseffekt, der dafür sorgt, dass aus der Umgebung einwirkende Informationen sich nicht mit ihren natürlichen Informationen vermischen. Zur Erhaltung ihrer energetischen Eigenschaften bedürfen diese Gesteine allerdings einer regelmäßigen kurzen Aufladung in der Natur. Aufgrund dieser positiven Eigenschaften werden sie gerne in der Heilmedizin eingesetzt.

Kritisch wird es allerdings, wenn Edel- und Halbedelsteine, Bergkristalle, Rosenquarz, Turmalin etc. zur Informierung benutzt werden. Ihre hohe Speicherfähigkeit ist zwar ideal für das Aufbringen von künstlich erzeugten Informationen, jedoch führt die Informierung zur Vermischung der vorhandenen natürlichen energetischen Informationen mit den künstlich generierten Informationen.

Weiterhin sorgt die durch die Informierung ausgelöste Aktivierung dafür, dass der Reinigungseffekt nicht mehr hinreichend funktioniert und diese Gesteine von nun an regelmäßig in immer kürzeren Abständen aufwändig gereinigt werden müssen.

Wie wichtig ist die Beachtung statischer Aufladung?

Statische Aufladung, die nicht wie oft missverstanden in den Bereich der Informierung gehört, sollte aus klanglichen Aspekten im Audiobereich unbedingt Beachtung finden.

Eine statische Aufladung erzeugt ein elektrisches Feld, welches den Signalfluss beeinflussen kann. Deshalb sollten alle im Umfeld der Audioanlage befindlichen Dinge (Geräte, Kabel, Lautsprecher, Möbel etc.) regelmäßig statisch entladen werden. Das geschieht am besten durch Abreiben der Oberflächen mit einem nebelfeuchten Tuch oder guten Antistatikmitteln.

Lebensdauer der LEDs

Wir verwenden nur hochwertige LEDs von namhaften Herstellern. Deren Haltbarkeit wird mit ca. 100.000 Stunden angegeben. Dies entspräche einem Dauerbetrieb von mehr als 10 Jahren und ist also keineswegs mit der Haltbarkeit gewöhnlicher LED-Leuchtmittel zu vergleichen.

Die Lebensdauer der LEDs verlängert sich deutlich, wenn sie bei Nichtbetrieb der Hi-Fi Anlage ausgeschaltet sind. Hierzu genügt es zumeist, den entsprechenden Schalter zur Anpassung der Leistungsstufe des Protektors in Grundstellung 0 zu bringen.